With numerous PCB manufacturers round, choosing one may be tricky. Manufacturers of printed circuit board (PCB) must have the right kind of expertise and experience, and if you’re putting an order, you need to verify some of the important particulars. On this post, we now have compiled a list of suggestions which will come useful find the correct manufacturer. 1. Check the fundamentals. How long has the corporate been in business? It is advisable to know a manufacturer inside out and the way in which they do enterprise within the trade. On the subject of electronics, experience is an aspect you can not afford to take without any consideration. 2. Can they handle your necessities? This is considered one of the primary questions it is advisable ask while you search for a PCB manufacturer. Some companies just deal with an ordinary set of specifications and tolerances, mainly because their production capabilities are restricted. If you’re in search of something very specific, you need a staff who can handle that.

3. Who’re their purchasers? PCB manufacturers work with numerous different purchasers in the electronics trade, and a few of them also deal with military orders. If you wish to know an organization higher, it’s good to examine their clientele and the kind of work they’ve finished for others. With a reputed identify, you do not have to fret about this side, because most details will probably be listed on their website, and the emerging firms will not thoughts sharing the references on request. 4. Will they provide engineering assist? That’s one of many early questions, as nicely. Before the actual money is spent on the fabrication process, you want an organization that can check all the features and can fully surrender to the needs of the consumer. They need to test the designs, so as to avoid all attainable errors sooner or later. A very good company may even spend considerably on enhancing their prospects and capabilities. 5. Quality matters. This is a cliche thing to say, however in terms of PCBs, quality matters greater than anything else.

You do not to spend your sources on an organization who wouldn’t guarantee that beforehand. Check their working capabilities and the kind of tasks they’ll manage for what you are promoting. On the subject of quality, you additionally must know their testing course of, PCB news especially for connectivity. For more on PCB news review our own internet site. 6. When can they deliver? Now, if you’re looking to place a fast order, you want to check this facet, as well. Many PCB manufacturers require more than a couple of weeks before they will ship your order, and that’s not one thing you would anticipate in the primary place. 7. Can they provide certifications? Some firms supply “UL 94V-zero fire resistance certification” on PCBs, and you might wish to examine for different relevant certifications, as nicely. In brief, the worth you pay should be well worth the products you get. Finally, do ask particulars of their vendors for materials supply. With PCBs, it’s a must to be extra cautious about each side. Take your time to guage these aspects, and you’ll all the time thank us later.

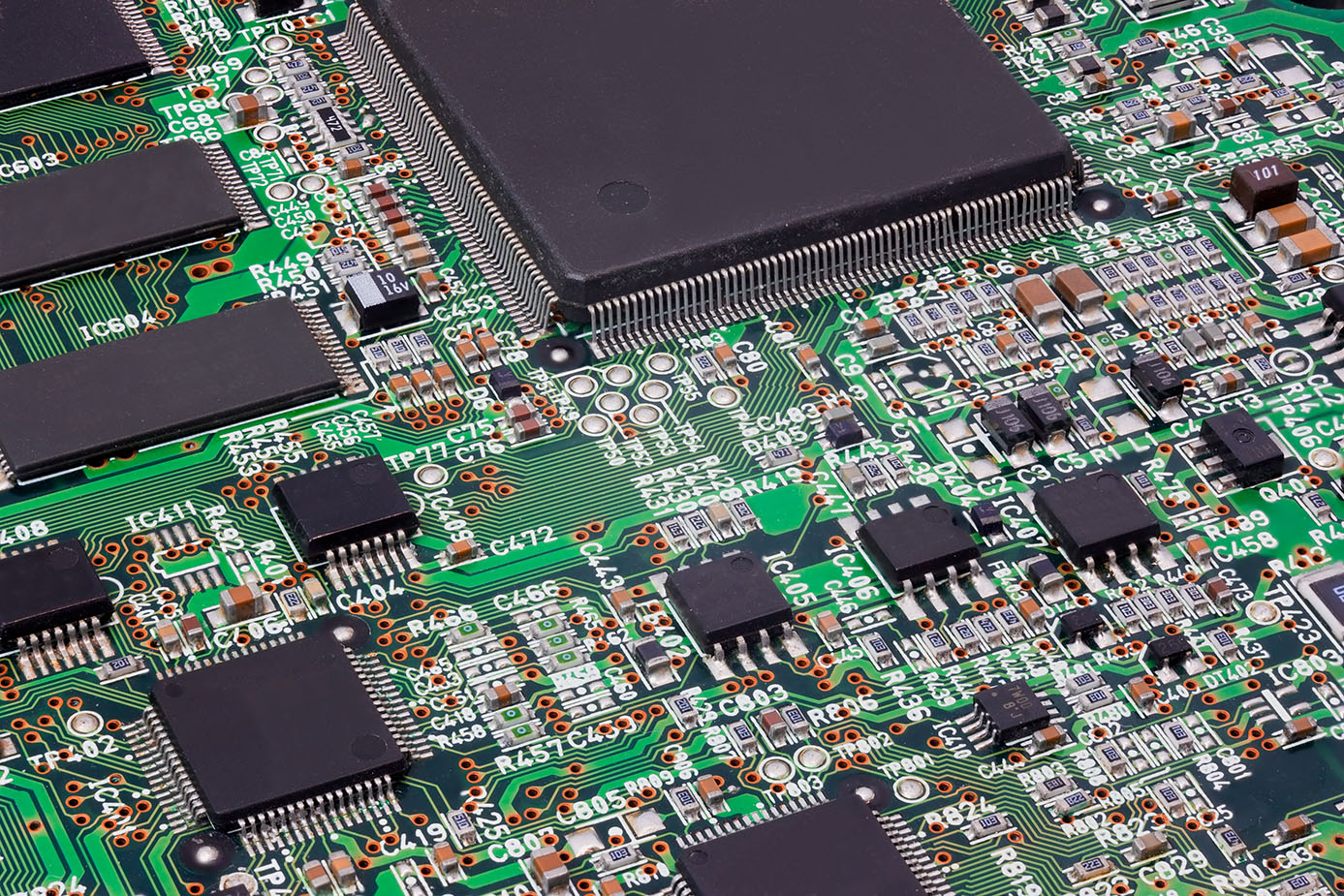

PCB board is the mother of electronic merchandise. Most digital equipment and merchandise have to be equipped PWB Board. Printed circuit board are often referred to as PWB, also have many peoples referred to as PCB substrate. Because the printed circuit board shouldn’t be a normal terminal product, the definition of the name is slightly complicated. For instance, the motherboard for private computer systems known as the mainboard, and cannot be directly referred to as the circuit board. Although there are circuit boards in the motherboard, They aren’t the same, so when evaluating the trade, the 2 are related but cannot be said to be the same. Another instance: because there are integrated circuit components mounted on the circuit board, the information media name it an IC board, but in reality, it is not equal to a printed circuit board. We usually say that the printed circuit board refers back to the bare board-that’s, the circuit board with out upper components.

In line with the variety of digital board layers, it may be divided into single-sided, double-layer, 4-layer, six-layer, and other multilayer circuit boards. And continue to develop within the path of excessive precision, excessive density, and high reliability. Continuously shrinking volume, decreasing prices, and bettering efficiency have enabled printed circuit boards to keep up robust vitality in the event of future electronic products. The future development pattern of PWB manufacturing know-how is to develop within the path of high density, excessive precision, wonderful aperture, positive wire, small pitch, high reliability, multilayer, high-speed transmission, lightweight, and thinness in efficiency. The single layer is on an insulating substrate with a thickness of 0.2-5mm, just one floor is coated with copper foil, and a printed circuit is formed on the substrate by printing and etching. The single panel is straightforward to manufacture and simple to assemble. The double sided boards are printed circuits on both sides of an insulating substrate with a thickness of 0.2-5mm. It’s suitable for digital merchandise with general requirements, resembling digital computer systems, electronic devices and meters.